Installation suggestions

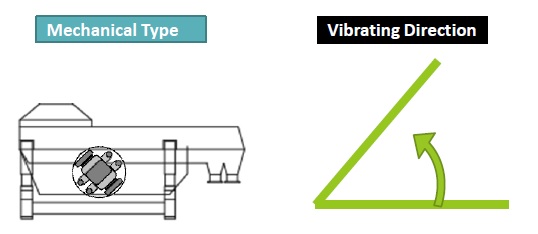

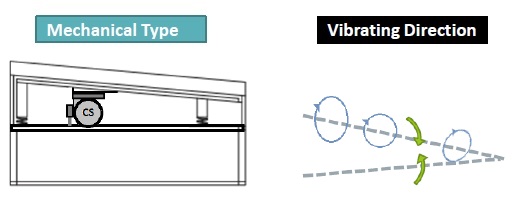

Type (A)

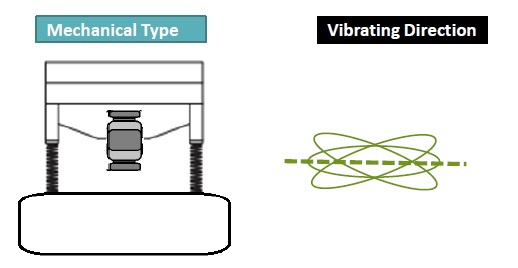

Type (B)

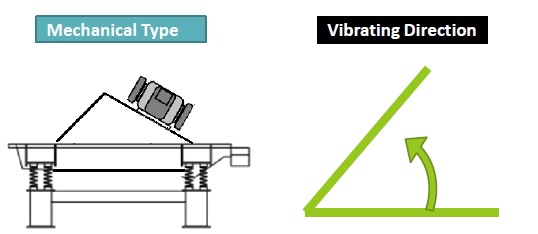

Type (C)

Type (D)

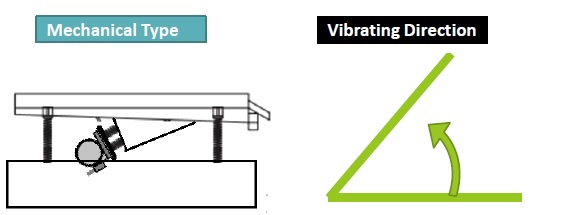

Type (E)

Mounting Instructions Checklist

¨ Determine vibrator placement on equipment.

¨ Determine length of channel iron and style of mounting plate.

¨ Attach vibrator to mounting plate. Check the mounting plate for warping & Shim if necessary.

¨ Install safety chain or cable.

¨ Take a voltage reading while vibrator is running.

¨ Take an amperage reading while vibrator is running.

Instruction Reminders & Suggestions

Vibration Motor placementFor coarse materials: mount vibrator 1/3 of the distance from the discharge opening to the top of the sloped portion of the bin.

For fine materials: mount vibrator 1/4 of the distance from the discharge to the top of the sloped portion of the bin.

Mount on iron/steel channel

Overall length of vibration motor unit should be perpendicular to length of channel, otherwise it may cause flexing & the vibrator may overload or standard burn out.

Restraint

Always Install Safety Cable or Chain: Mount one end to the vibrator and the other to the hopper or bin above the vibrator. Do Not Attach To the Mounting Plate

Operation temperature

If the ambient temperature of the area exceeds 104°F (40°C) OR if the skin temperature of the application exceeds 150°F (66°C), Please check situation of vibration motor, over temperature may reduce the lift-time of bearing

General Maintenance

Under normal usage conditions, the suggestion check and maintenance should be conducted once every 3,000 hours or 4.5 months of operation especially in dust operation environment. Please follow “Bearing maintenance” and “Mounting instructions checklist” to check.Bearing Maintenance

For Horsepower 2HP and up models (2 HP included)CSV recommends the use of Shell Oil’s Alvania Grease #3 as a bearing lubricant. This is a special lubricant designed for motor vibrator bearings and similar applications where shock is involved. Alternate greases are Shell’s #2 and Mobile Oil’s Mobilux #2 or #3. Suggestion time is 1500 hours but do not over 2000 hours or 3 months

For Horsepower below 2HP models

The bearings are sealed and factory lubricated for the life of the bearing. When the bearing life expires on these models, simply replace the bearing entirely. If you need suggestion bearing, please contact CSV

Fuse/Overload Protection

All Model CSV motors require a proper protective overload circuit. If the CSV motor is not operated with the proper overload protection (heaters), all factory warranties are null and void.Troubleshooting Checklist

My material still in not moving1. Did you put your vibrator in the right location?

2. Did you mount your vibrator properly?

3. Do you have the right vibrator for the job?

4. Does it provide enough force?

5. Is it the right frequency?

6. Is it set to the maximum force?

The vibration motor do not start

1. Check power supply to unit. Are you getting the proper voltage?

2. Check for blown fuses in fuse/overload protection circuit

3. Are you running the vibrator continuously? Check bearing condition and doing maintenance.

4. If fuse/ protective overload circuit is in working status and power is correct provides, please check current status

General Precautions

1. Observe the safety regulations that are applicable to the equipment that will be used with the CSV motor and the location where the CSV motor will be installed. (These regulations include the safety, health and occupational regulations, the technical standards for electrical equipment, the interior wiring regulations, the explosion protection guidelines for factories, Building Standards Law and so on.)2. Select the CSV motor that is applicable to the intended application and usage environment.

3. In food processing equipment or other equipment that must be protected from oil, install oil pans or other forms of protection against oil leakage resulting from equipment failure or problems caused by the equipment nearing the end of its service life.

4. Before using the CSV motor, read the whole related documentations and regulations carefully to ensure correct usage.